There is much discussion about supply chains and supply ecosystems but what’s the difference?

In a recent World Commerce & Contracting research project we created the descriptions below to help us understand the differences and benefits:

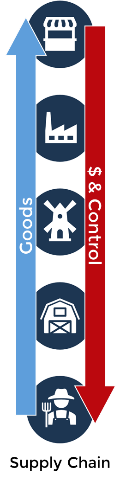

Supply chain is a commonly used term in many contexts and, just as with terms such as ‘innovation,’ can mean different things to different people. It is readily interchanged with the terms supply networks and supply ecosystems. In the context of this research, we use the term Supply Chain to mean a series of tiered supply relationships where each supplier only has a singular relationship to the tier above them and one or more relationships in the tier below them. It is simplistic in structure – relationships and information typically flow vertically up and down.

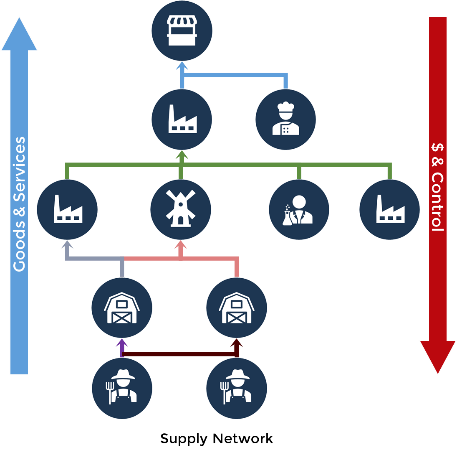

A supply network is an evolution of the supply chain and, due to complexity, there are links not only vertically but potentially horizontally to suppliers in the same tier. However, data and information flows are still predominantly vertical in nature with goods and services flowing up and $ reward, risk and control flowing downwards. Links within the network typically remain static and defined.

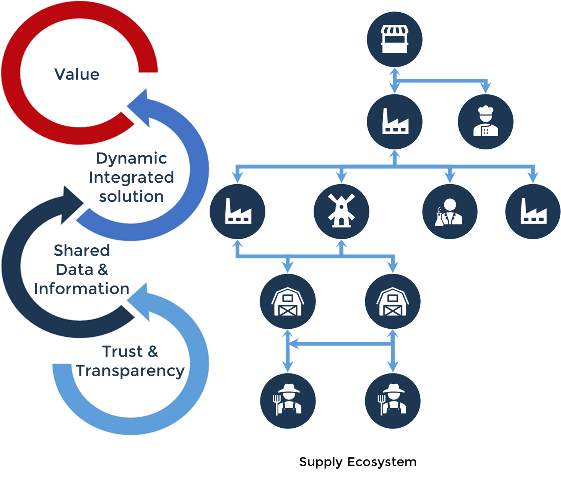

Supply ecosystems take the concept of a supply network one step further in removing the linear nature of supply chains and networks. In a supply ecosystem, the links are more dynamic and change over time depending on the context of requirements. To facilitate this there is likely to be greater equality of visibility between players in the supply ecosystem. As shown in the diagram, this is not a case of ‘fluid chaos’ of data flows, but rather where data flows in a planned and controlled, yet dynamic manner.

While these definitions are relatively simplistic they help us to visualise the differences and similarities between. It also allows us to become more sophisticated in when we deploy them as each has their own merits, costs, and benefits. None of them are good or bad, right or wrong, it’s about using the most appropriate model for the context aligning the costs and benefits.

For example, a supply chain is likely to be beneficial where there is a simple linear supply of a mature, well defined product. It may be that multiple products, each with distinct and separate supply chains are combined by a buyer into a final product or service such as bringing together a cup, milk and coffee to make a cappuccino.

Where the product/service is more complex and requires multiple components to be brought together into sub-assemblies but where limited visibility or transparency is required as the sub-assemblies are well defined and known, then a supply network may be the most appropriate. An example of this could be the manufacture of a PC where various components using standard interfaces are assembled into the final product.

At the most complex end of the continuum we have supply ecosystems. These are most useful where there is a greater need for visibility and transparency through the sharing of data and information. Perhaps as a result of a greater level of uncertainty in terms of the ultimate deliverable or how it will be delivered. This could be the manufacture of a complex piece of consumer electronics or the provision of an outsourced service.

The three models above, chains, networks, and ecosystems, can be consciously combined in designing a project or portfolio with appropriate T&Cs, relationships, governance, and performance frameworks designed around them.

It’s only when we get to a level of maturity where we consciously design our commercial solutions that we are able to optimise and leverage the true value for an opportunity.